2 key steps you can take to minimize

warping, shrinking, checking or cupping

|

when the outdoor temperature begins to drop and the relative humidity

begins to fall, woodworkers may find themselves faced with

wood warping, checking, shrinking or cupping.

|

| Wood is a hygroscopic material, it tends to absorb moisture from or dissipate moisture to the air. Whether it absorbs or dissipates moisture is dependent upon it's moisture content in relation to the relative humidity of the surrounding air. No substance we are aware of today will stop the movement of moisture. We can slow it down tremendously, but are not able to stop it.

Problems with wood and moisture occur with imbalances. When relative humidity changes in the surrounding air, wood moves to equalize with it. If the moisture from the air is allowed to enter one face of a board readily and impeded on an opposing face, cupping typically occurs until enough time passes for the two faces to come into moisture content equilibrium.

When wood products are shipped across long geographic distances, the relative humidity present at the end location can vary substantially from the location of manufacture. Packaging can help alleviate problems during shipping, but proper handling after receipt by the end user is also required. Typically an equalization period should be allowed before installation of wood components. This allows the wood time to acclimate to its new location and the corresponding relative humidity.

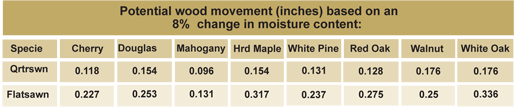

Another rule experienced woodworkers learn is solid wood shrinks and expands in three dimensions. Tangential to the growth rings, Radially to the growth rings, and Longitudinally. Tangential shrinkage from green lumber state to oven dry state is the greatest and for hardwoods varies from 6.3% to 11.9%. Radial shrinkage varies from 3% to 7.7% and Longitudinal varies from 0.1% to 0.2%. As you can see, longitudinal shrinkage is very slight in comparison to the other two.

The next consideration is what is the moisture content of green hardwood lumber? According to the U.S. Department of Agriculture's Wood Handbook, the moisture content of green hardwoods vary from 150% down to 44% dependent upon specie and whether you are measuring heartwood or sapwood. For most applications in the United States 6% to 8% moisture content is where lumber should be to start fabrication in the winter months. 8% to 12% moisture content is fine for most applications in the summer months. Musical instruments are a different animal and require dryer conditions than most applications and 3% to 4% is typically required. In any case, knowing what your relative humidity is and knowing your design takes into account wood's hygroscopic nature are both requirements of successful woodworkers.

|

|

|

PORTABLE MOISTURE METERS

|

PORTABLE MOISTURE METERS ARE NICE TO HAVE AVAILABLE WHEN YOU NEED A QUICK DECISION ON MOISTURE CONTENT

|

| Sixty years ago, portable moisture meters were built inside a wooden box the size of a car battery. Fortunately times have changed. We have been selling Lignomat pin-type meters for over 26 years. Around 2003, Lignomat introduced the Pinless Ligno-Scanner D. It became a favorite immediately with our employees because it was small, easy to use and didn't leave holes. But despite all this, we wanted to know if we could trust it.

Our own Dan Lampman, with over two decades of experience in hardwood manufacturing and inspection, spent considerable time researching and evaluating pinless moisture meters on the market to verify their accuracy. Dan compared the Ligno-Scanner D to over 1,000 oven shell and core samples from incoming loads of lumber for 2 years. Included in the research were 2 additional pinless meters costing 2 to 3 times as much as the Scanner D. All performed well with some exceptions just as oven tests can vary in accuracy. The results -- our yard foreman uses the Ligno Scanner D regularly, and we readily recommend it to customers and have them available for purchase at both our Charlotte MI and South Bend IN locations.

|

drying your own lumber - proper techniques

|

WHEN WOOD IS NOT PROPERLY DRIED, ACCELERATED SHRINKING CAN OCCUR. THIS STRESS CAN TEAR THE WOOD FIBERS APART, CAUSING INTERNAL DEFECTS IN LUMBER SUCH AS CHECKING, CASEHARDENING, AND HONEYCOMB.

|

| You probably know wood has to be dried in order to be useful as lumber. Removing the water makes the material dimensionally stable, accepting of glues and finishes and much better machineability.

The moisture content of a piece of wood is the ratio of the weight of the water in it to the weight of the wood fibers if they were completely dry. Usable lumber is produced by reducing the moisture content of green wood (sometimes well over 200 percent) to 12 - 18 percent by air drying, or to 6 - 10 percent by kiln drying. Whether dried naturally, or in a kiln, wood dries to a certain percentage, and then stops. The relative humidity of the air around the wood determines this point, called equilibrium moisture content (EMC). This is why you always should let your wood acclimate to the conditions or relative humidity that is eventually desired before beginning any woodworking job…As a point of reference the guys at Gibson Guitars shared their recipe for humidity in the shop…

“A Gibson acoustic guitar is built in a controlled environment. Gibson maintains a 40% to 50% level of humidity at an average temperature of 70 degrees in the shop where each guitar is created. If a guitar is deprived of this level of humidity (lower than 40%) for an extended period, you may notice that the string height will lower, causing excess string buzzing. In extremely dry conditions, irreversible damage can occur (cracks or checks in the finish and or wood).

To understand a little more about moisture in wood a simple anatomy of a wood cell may be helpful. The three basic types of moisture in wood cells are:

Bound water - This water is held in cell walls, some typically remains behind in “dry” wood.

Free water - Water stored in the cell cavity. It is removed completely during the drying process.

Water vapor – Small amounts may remain in the cell cavity, even in “dry” wood.

As wood dries, the first to go is free water, second is the bound water. Eventually, moisture loss stops, leaving some bound water and, possibly some residual water vapor in the wood cell cavity. Once the free water is removed and then the (tougher) bound water is reduced, the cell walls of the wood will shrink, causing the wood to change dimension. Because wood cells vary in size, density, and orientation, they can often shrink unevenly, causing boards to warp in many various ways. As well wood dries from the outside in, as the water it contains moves naturally from areas of highest to lowest concentration. This creates uneven pressures in the outer portion or shell and the inside of the board or core. Wood becomes most stable when it reaches EMC, as stated before, EMC is controlled by relative humidity. Wood is described as hygroscopic, (as the people at Gibson Guitar know very well) meaning it will continue to take on and shed moisture and, because of this, expand and contract. To minimize these problems, you can try and shy away from boards that show wild figure, or inconsistent growth-ring spacing. In addition when wood is not dried properly, accelerated shrinking can occur. If not properly relieved, this stress can tear the wood fibers apart, causing internal defects in lumber such as, checking, casehardening, and honeycomb.

Dealing with a reputable lumber supplier that practices proper drying techniques is the best defense against drying defects in any lumber you purchase. Next is safely storing your lumber prior to working with in your shop or factory with proper de-humidification and or humid-ification. All that being said the final and most important step is to always take into account wood movement when designing with wood. Experience has taught woodworkers of old how to deal with wood’s dimensional changes due to moisture. The answer was joinery that allowed for seasonal wood movement. And despite today’s super-strong glues and moisture-resistant finishes, that’s still the answer. Stile-rail-and-panel construction for cabinet and doors, wall panels, and sections of furniture, for instance, didn’t come about by accident. Joiners, as woodworkers’ centuries ago, figured out that a rectangular panel could be maintained in position with a solidly secured frame of wood. However, the panel must not be glued or nailed in place in the frame. Instead, it has to “float” in grooves, free to shrink and swell with changes in atmospheric moisture. Today, some professional woodworkers talk about “nickel and dime reveals” on flush-fitting cabinet doors and drawers. These refer to the space you should leave between the wood that you expect will shrink or swell — the doors or drawers — and the carcass or frame of the piece. “If you build in winter, make the reveal the thickness of a nickel.” That leaves room for the wood to swell when the humidity goes up. On the other hand, “Build in summer, use a dime,” means that you’re allowing for the shrinkage that will come in winter. If your woodworking tastes and designs are those of a fine quality “Gibson Guitar” then controlling humidity and temperature is key.

In calculating water content, moisture content (MC) tells us the ratio of the weight of water in a piece of wood compared to its weight completely dry. We express it as a percentage. To determine MC, first weigh a piece of wood. Then, dry it until it contains no water (determined when weight loss stops). Next, compare the weights as follows:

(wet weight – dry weight) = mc dry weight

For example, if a piece weighs 25 lbs. wet and 20 lbs. dry, its MC equals 25 percent: (25-20)/20 = 5/20 = .25 or 25%. Thankfully, there are quicker ways to determine MC with simple moisture meters, however, nothing beats the accuracy of a fine set of scales and oven, then utilizing the above procedure and formula.

|

|

|

pinless lignomat ligno -scanner d |

| The Ligno-Scanner D gives true wood moisture readings in percent using built-in corrections for different species. For ease-of-operation a HOLD function is built-in.

With a pinless meter you can quickly scan a large number of boards. Pinless meters are essential when checking finished products such as cabinet doors, table tops and ready-to-sell furniture, where pins would leave visible marks. Ideal for building inspectors to assess moisture conditions and water damage in buildings, especially since Scanners can also be used for non-wood building materials such as drywall, concrete, tile, etc.

For pricing and availability, email us, or call 800-292-5937. |

| |

| |

| |

|