| |

| |

| |

EMAIL US | | |

| L.L. JOHNSON LUMBER MFG. CO. | & JOHNSON'S WORKBENCH |

| EVERYTHING FOR THE | WOODWORKER |

|

|

WE'VE GOT BUNK QUANTITIES OF BALTIC & UV2 MAPLE PLY PERFECT FOR CABINET SHOPS! We have plywood in bunk quantities for constructing your cabinet boxes. These dimensionally stable, economically priced sheets will be kind to your budget. Also perfect for building exhibits, displays, built-ins, just about any commercial or residential project requirements.

Find Baltic & UV2 Maple Ply product listing with pricing at left Or call us for a quote - 800-292-5937.

USE MARINE PLYWOOD WHEN MOISTURE IS A PRIORITY Marine plywood is manufactured to the highest standarads, from durable face and core veneers, with few defects so it performs longer in humid and wet conditions and resists de-laminating and fungal attack. This type uses top quality adhesives and is most commonly graded as A-A, with two top grade faces. Pricing is below left.

MAKING SENSE OF MARINE PLYWOOD CHOICES The many options and price points available to fulfill a wide range of marine applications make it important to understand the trade-offs. Read more...

BS1088 LLOYDS REGISTER & BS6566 CORE QUALITY: WHAT ARE YOU REALLY GETTING? Known to be the toughest standards in plywood manufacturing, boat builders in the United States are requesting more and more that their plywood be made to the British Standard 1088 or British Standard 6566. Read more... Boat builders in the United States are requesting more and more that their plywood be made to the British Standard 1088 (BS1088) or British Standard 6566 (BS6566)

WHAT DO YOU GET FOR THE PRICE? Prices listed are per sheet. 1 thru 10pc pricing may be obtained by mixing thicknesses and specie. 25pc pricing is for same thickness and specie. 25pc Bunk may contain up to 10% Shop Grade (a couple sheets may contain slight defects), and are special ordered.

DIMENSIONS 4’x8’ sheets in stock. Other sheet sizes available by special order with minimum quantity requirement. Thickness: 1/8”, 1/4”, 1/2”, and 3/4” in stock. Other thicknesses available by special order. Call for more details 800.292.5937.

QUALITY ASSURANCE Our European Birch plywood is produced by a quality controlled process using a superior glue bond coupled with a multi-ply design, giving the plywood superior strength, rididity and dimensional stability. The foreign grading system uses alpha designations to refer to the quality of the plywood B(S), BB, CP, L, and C with B(S) being the best. The first set of letters refers to the face. The second set refers to the back.

HALF SHEETS AVAILABLE For your smaller plywood projects, we have half sheets, with minimal damage, of many species -- all at garage sale prices. Call us at 800-292=5937.

PLYWOOD TERMINOLOGY PLYWOOD SURFACE GRADES A-1, A-4...These alpha-numerical designations refer to the grade of the plywood face and back surfaces. Plywood can have faces and backs of different grades. The letter identifies the face surface grade while the number identifies the back surface grade. Face Grades range from A thru E, with A being the best. Back Grades range from 1 thru 4, with 1 being the best. Plywood with a 1 or 2 back grade will have the face and back of the same specie. Plywood with a 3 or 4 back grade can have a back surface of a different specie than the front surface.

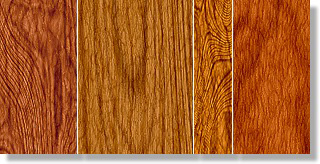

PLYWOOD SURFACE GRAIN PATTERNS There are two ways to influence the plywood surface grain pattern -- by the types of veneer cuts, and veneer matching during the glueing process.

1. VENEER CUTS: Depending on the manner in which a log is cut, strikingly different visual effects can be achieved with the wood’s grain and characteristics. Two logs of the same species, cut in different ways will produce distinctive veneers.

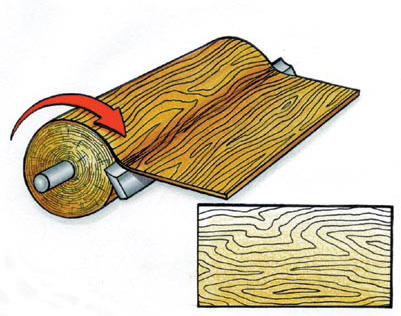

ROT (Rotary Cut): The entire log is cut or “peeled.” It can yield full sheets of veneer with broad grain pattern.

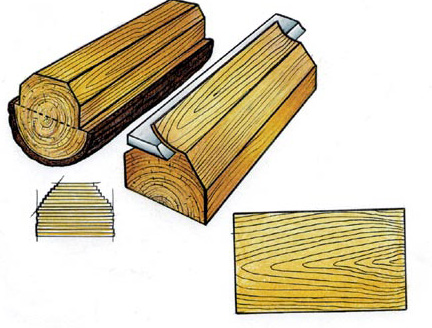

PS (Plain Slicing): The flitch, with the heart side against the slicer table is cut parallel to a line through the center of the log.

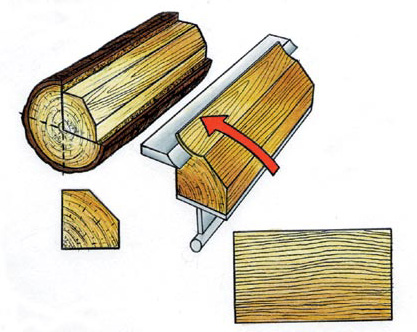

RC (Rift Cut): A cut angle of 15 degrees to the radius of the flitch (half log) is used to minimize the ray flake affect in oak.

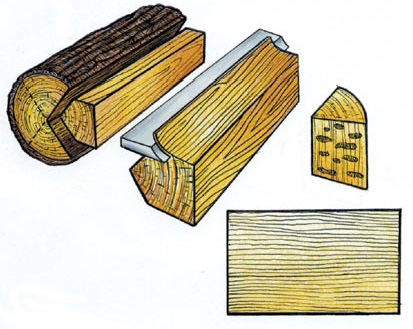

QS (Quarter Slicing): This method prodcuces a series of stripes -- straight in some woods, varied in others. Most species have the same look as rift cut.

2. VENEER MATCHING: The natural coloration and arrangement of a veneer panel face determines the resulting visual effect. Different matching techniques are used for specific panel applications.

BOOK MATCH: Every other piece of adjacent veneer is turned over, resulting in identical, but opposing patterns.

PLEASING: Veneers are matched by color or similarity, not necessarily by grain characteristics.

RANDOM: Veneers intentionally do not match at the joints, providing a casual effect.

SLIP MATCH: Adjacent veneer sheets are joined side by side, same sides up, for a uniform grain pattern. |